The Carbon Filtering Process is generally used for Indoor Air Purification/(quality), (Odor) control and (emission control) Processing. Activated carbon is a general term of adsorbents that have been manufactured from a variety of carbon-based materials. Each base material results in an activated carbon with unique physical characteristics that determine its suitability for treatment applications.

The ability of activated carbon filters to remove impurities from the air is one of the reasons it is commonly used for indoor air quality, odor control and emission control systems. Carbon Filter use continues to increase as more industries and consumers consider their environmental impact.

Carbon Filters are generally used in:

- Landfill Lechate

- HVAC Systems

- Odor Control Systems

- Emission Control Systems

- Municipal water Treatment Facilities

- Spray Booths

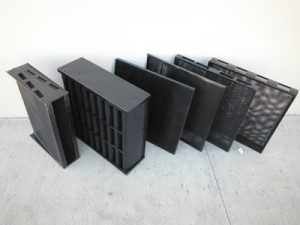

There are different types of carbon medias which Pure Effect, Inc. uses in their carbon filters:

- Standard Activated Carbons- Used to remove VOC and Odors

- KMNo4 Blend Medias- specialty gasses such as sulfur oxides and ammonia

- Specialty Impregnated Carbons- used to remove compounds such as mercury, H2S and cyanide.

Once the carbon has reached its capacity it is considered “spent”. You can determine the life remaining on your carbon filters by sending a sample to Pure Effect for testing. If the carbon is “spent” the carbon filter may be recharged or replaced with new filters. With our large inventory of used filters for exchange, we guarantee your system will only be shut down for a short period of time. Please contact us at 714-639-7873 or sales@pureeffect.com for testing.

Leave a comment!

You must be logged in to post a comment.